Revolutionize Your Ride with Cutting-Edge Airless Tires

Discover the ultimate in durability, comfort, and eco-friendly innovation with puncture-proof, maintenance-free smart tires tailored for the modern driver.

Discover the ultimate in durability, comfort, and eco-friendly innovation with puncture-proof, maintenance-free smart tires tailored for the modern driver.

The automotive industry has always been a pioneer in innovation, and one of its most transformative advancements is the emergence of the airless tire. Imagine a future where flat tires are obsolete, maintenance is virtually eliminated, performance remains consistent in all driving conditions, and wheels evolve into intelligent systems embedded with sensors and active/reactive technologies. Once a vision of the future, airless tires are now becoming a reality, set to revolutionize the way we drive.

Known as non-pneumatic tires (NPTs), airless tires operate without the need for air. They are constructed from advanced materials such as rubber, resin, and hybrid composites, designed into a sophisticated cellular structure that absorbs shocks and ensures consistent performance without inflation. Unlike traditional pneumatic tires, airless tires are immune to punctures, eliminating the need for regular inflation and drastically reducing maintenance demands. Additionally, their integration with embedded sensors and active/reactive systems makes them an intelligent solution, capable of monitoring performance, adapting to driving conditions, and paving the way for smarter, more efficient vehicles.

Leading innovators in the field, including Michelin, Bridgestone, and Goodyear, are driving advancements in airless tire technologies, heralding a new era in tire performance and durability. Michelin pioneered the development of airless tires with the introduction of the Tweel in 2005, depicted in the left figure. Bridgestone followed with its concept airless tire in 2012, illustrated in the right figure.

A notable milestone occurred in 2019 when Michelin partnered with General Motors to unveil the Uptis (Unique Puncture-proof Tire System), an advanced evolution of the Tweel. This innovative design, which achieved a lighter weight compared to conventional tires and wheels of the same size, is scheduled for production in 2024, with plans to debut on GM’s Chevrolet Bolt electric vehicles—a significant step toward the mainstream adoption of airless tire technology. However, Michelin’s ability to meet its ambitious 2024 production goal remains uncertain.

Despite decades of research and development, airless tires have yet to become a standard feature in everyday passenger vehicles. Although they offer significant advantages, several challenges have slowed their path to widespread adoption. Below are the key reasons why airless tires are not yet mainstream:

Traditional pneumatic tires excel at providing a smooth and cushioned ride by absorbing shocks and vibrations through air pressure. In contrast, early airless tire prototypes struggled to match this level of comfort, often transmitting more road vibrations to the vehicle cabin. While advancements in material engineering and structural design have improved ride quality, achieving the same or better comfort as air-filled tires remains a challenge, particularly for passenger vehicles where comfort is a priority.

Managing heat buildup is a critical technical challenge for airless tires. Unlike pneumatic tires, which dissipate heat through their air-filled structure, airless designs tend to generate and retain more heat during prolonged use, especially at high speeds. This increased heat can compromise tire performance, accelerate wear, and raise safety concerns. Advanced materials and innovative structural designs are being explored to address these limitations, but solutions remain in development, limiting their readiness for mainstream applications.

Airless tires require cutting-edge materials and advanced manufacturing techniques, such as precision molding and intricate structural designs. These factors make them significantly more expensive to produce compared to traditional pneumatic tires. While their durability and longer lifespan could offset these costs in the long run, the high upfront investment remains a barrier for both manufacturers and consumers. Until production processes are streamlined and costs reduced, airless tires will remain a niche product.

In certain key areas, airless tires face performance limitations compared to their pneumatic counterparts. For example:

These performance trade-offs remain a critical area of improvement for airless tire technology.

The automotive industry has heavily invested in pneumatic tire technologies and the infrastructure that supports them, including manufacturing facilities, tire repair services, and recycling systems. Transitioning to airless tires would require significant changes to production lines, supply chains, and service ecosystems. Additionally, consumer awareness and trust in airless technology need to be established to drive demand, further complicating the shift to this emerging technology.

While airless tires are not yet ready for widespread use, ongoing advancements in materials science, structural engineering, and manufacturing processes hold great promise. Innovations such as new polymers, heat-resistant composites, and advanced simulation techniques are addressing current limitations. Additionally, the growing adoption of electric and autonomous vehicles is creating opportunities for airless tires, particularly where durability, reduced maintenance, and integration with intelligent systems are prioritized. With continued investment and innovation, airless tires have the potential to become a viable and transformative option for everyday drivers in the near future.

We are at the forefront of airless tire innovation, eliminating the need for air pressure while delivering enhanced safety, reduced maintenance, and a smoother, more reliable driving experience. Our pioneering designs are set to revolutionize mobility across a wide range of vehicles.

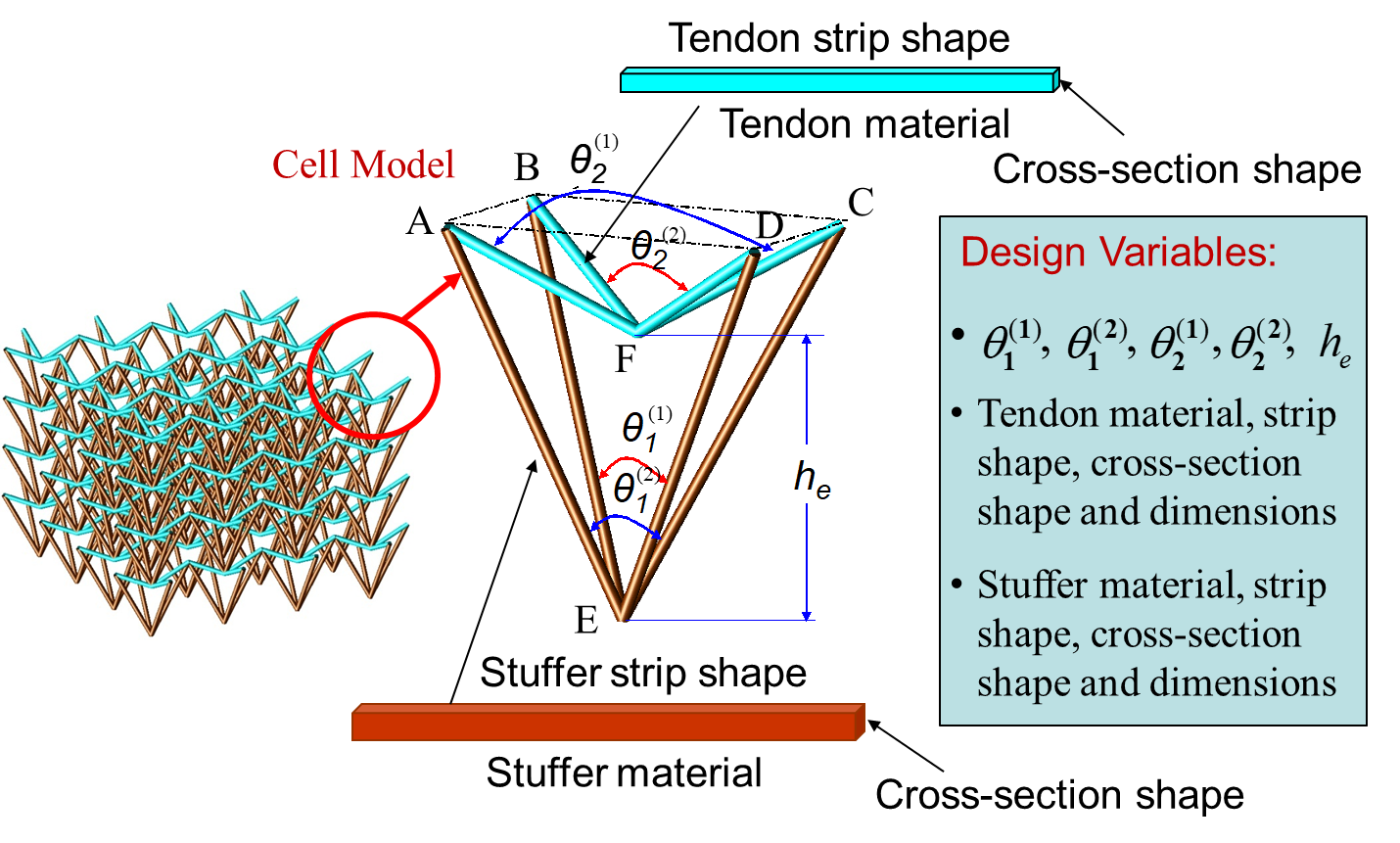

In 2010, we unveiled metaTire™, a groundbreaking non-pneumatic tire that leverages our patented Negative Poisson’s Ratio (NPR) architectured cellural metamaterial as illustrated in the following figure. (Reference: Ma, ZD. Macro-architectured cellular materials: Properties, characteristic modes, and prediction methods. Front. Mech. Eng. 13, 442–459 (2018).)

This advanced material offers several unparalleled benefits:

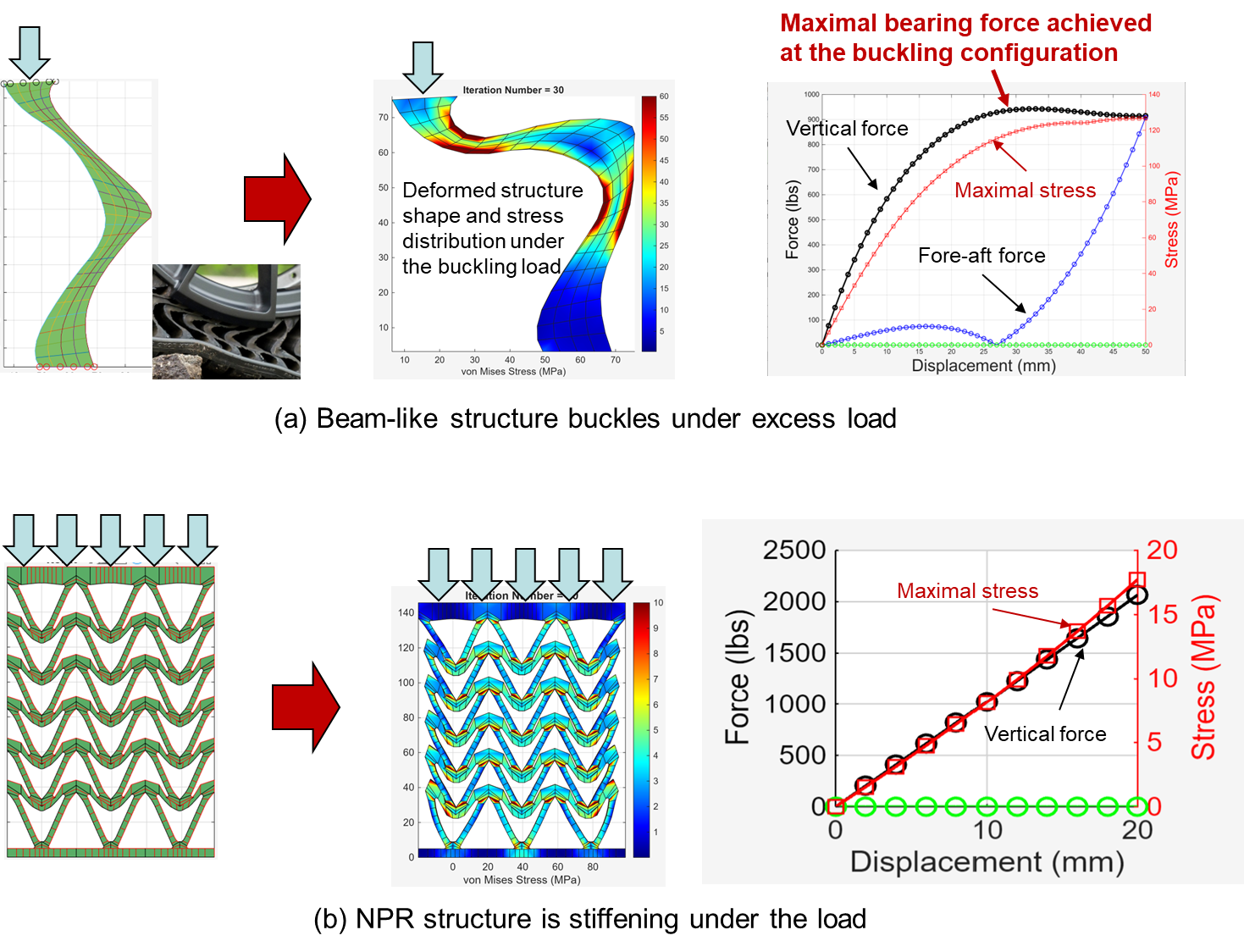

Our metaTire™ is engineered using our proprietary Negative Poisson’s Ratio (NPR) architectured cellular meta-material, which has been developed and patented exclusively by us. Figure 3 highlights the significant advantages of the NPR structure over conventional beam-like structures.

Figure 3(a) presents our CAE nonlinear simulation results for a beam-like structure, similar to the one used in Michelin's Uptis, under compressive loading conditions. In Figure 3(a), the left panel displays the three-dimensional simulation model, the middle panel illustrates the deformed structure shape and stress distribution under the buckling load, and the right panel depicts the load-displacement curve obtained from the simulation.

As shown in the right panel, the beam-like structure exhibits progressive softening (i.e., decreasing stiffness) as the load increases until it reaches a critical point. At this critical point, the structure undergoes buckling, losing its ability to support additional load. This buckling behavior presents a major limitation for airless tire designs employing similar beam-like structures.

Moreover, the middle panel of Figure 3(a) reveals that buckling induces stress concentrations in localized regions (marked in red), which further complicates the durability design of airless tires.

In contrast, Figure 3(b) showcases our CAE nonlinear simulation results for an NPR structure, similar to the one integrated into our metaTire™, under compressive loading conditions.

The left panel of Figure 3(b) displays the three-dimensional simulation model, the middle panel illustrates the deformed structure and stress distribution under the maximal load, and the right panel presents the load-displacement curve from the simulation. As evidenced in the right panel, the NPR structure stiffens as the load increases, without exhibiting buckling, and continues to support additional loads.

Furthermore, the middle panel of Figure 3(b) demonstrates that deformation under maximal load results in more evenly distributed and significantly reduced stress throughout the NPR structure. These unique characteristics of the NPR structure enable wide-ranging, high-performance design applications for our airless tires.

Compared to existing solutions, the metaTire/n-Wheel concept significantly expands the design space and application range of non-pneumatic tires. The goal of metaTire™ is to achieve lighter weight, longer tire life, and better performance in terms of drivability, durability, NVH (Noise, Vibration, and Harshness) characteristics, load-carrying capability, fuel efficiency, and design flexibility compared to current pneumatic and non-pneumatic tires

The exceptional properties of the NPR meta-material make metaTire™ a versatile and high-performance solution for modern vehicles. Additional insights into these capabilities are provided in the accompanying PowerPoint presentation.

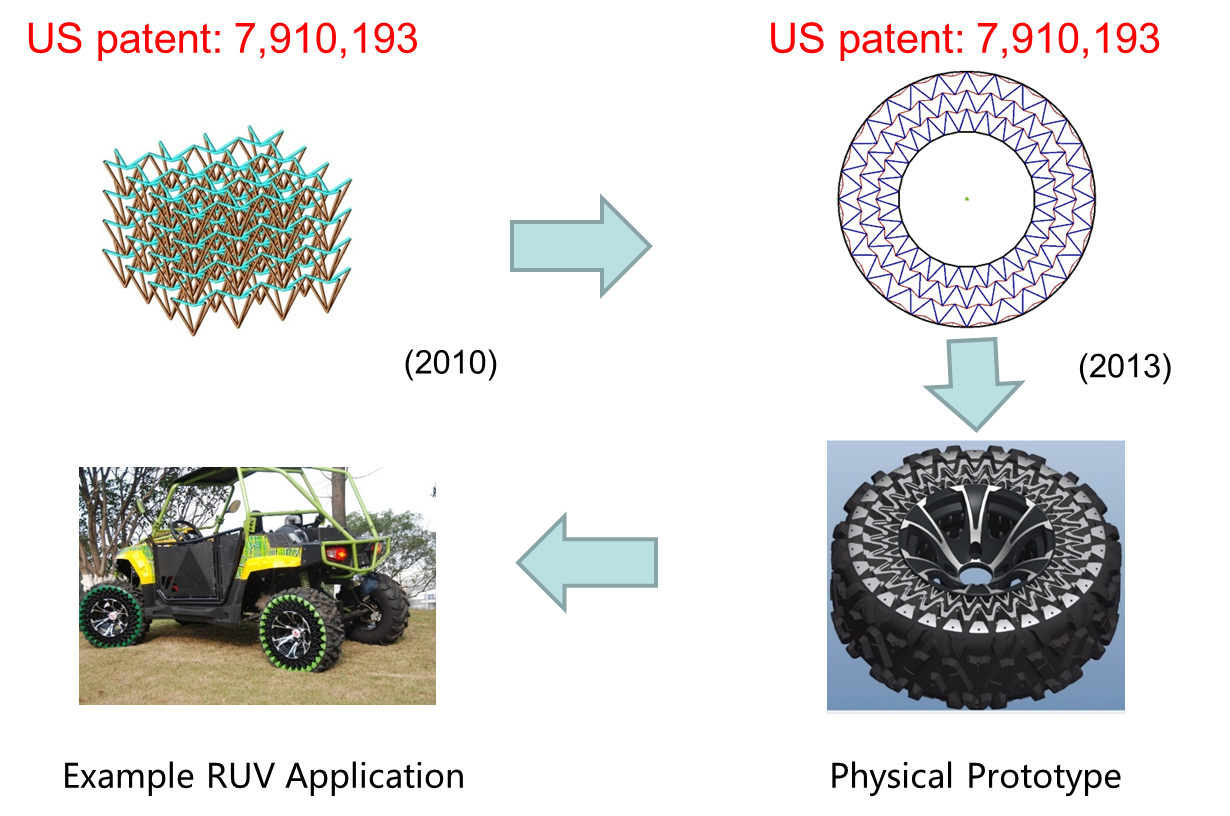

When paired with an integrated wheel rim system, metaTire™ transforms into n-Wheel™, an advanced, adaptable solution. This technology has been rigorously tested on multiple vehicle types showing Figure 4, demonstrating its versatility and reliability:

Especialy the following applicable vehicles should be mentioned:

Results from extensive road testing have validated the performance of n-Wheel™ across these applications, with more details to be shared in subsequent slides.

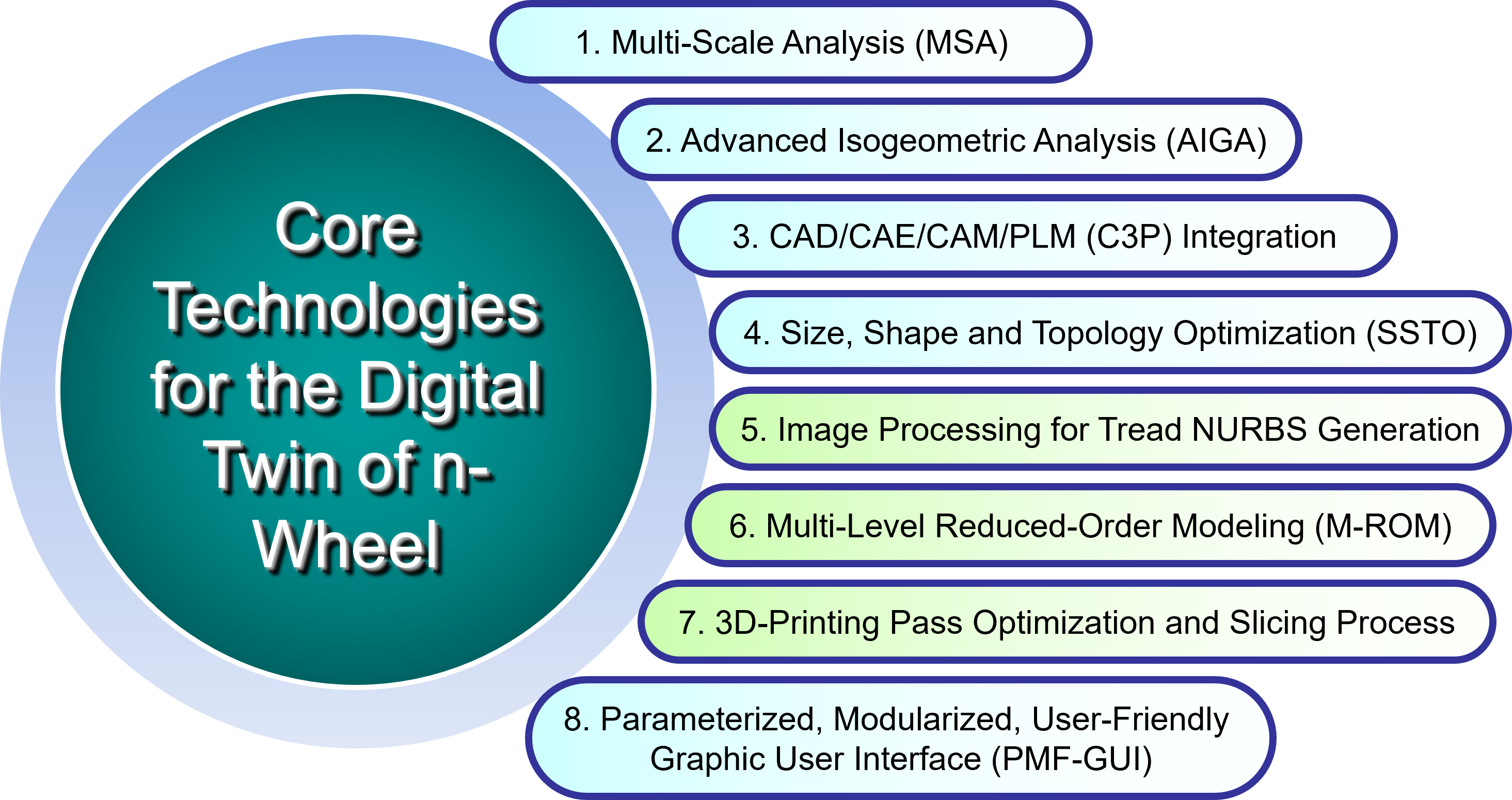

N-Wheel Technologies, Inc. has developed a suite of groundbreaking technologies for the design and optimization of metaTire and n-Wheel concepts. Figure 5 illustrates the core numerical enabling technologies of n-Wheel, developed exclusively by N-Wheel Technologies, Inc. As shown in Figure 5, these innovative technologies, many of which remain unpublished, include: 1. Multi-Scale Analysis (MSA), 2. Advanced Isogeometric Analysis (AIGA), 3. CAD/CAE/CAM/PLM (C3P) Integration, 4. Size, Shape, and Topology Optimization (SSTO), 5. Image Processing for Tread NURBS Generation, 6. Multi-Level Reduced-Order Modeling (M-ROM), 7. 3D-Printing Pass Optimization and Slicing Process, and 8. Parameterized, Modularized, User-Friendly Graphic User Interface (PMF-GUI). Further details will be presented in subsequent slides, and each technology will be comprehensively documented in upcoming technical papers to be published in the near future.

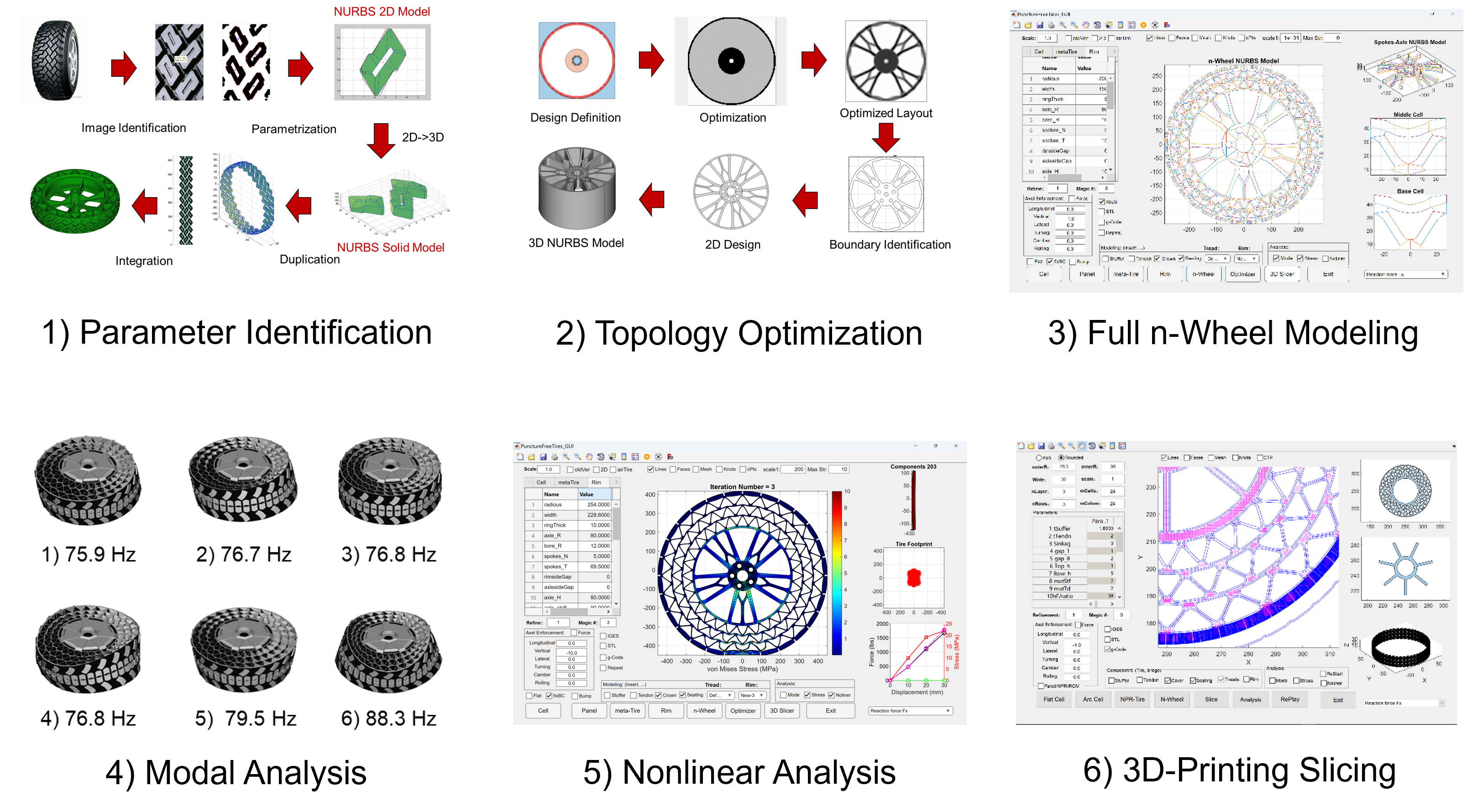

Leveraging advanced enabling technologies, N-Wheel Technologies, Inc. has developed a digital twin of the n-Wheel, called the Digital n-Wheel, to enhance and optimize the performance of the physical n-Wheel. Figure 6 highlights the key functionalities of the Digital n-Wheel, which include: 1) parameter identification and image processing for automated generation of the tread NURBS model, 2) topology optimization for innovative rim design and enhancement, 3) comprehensive modeling of the n-Wheel for diverse design and optimization challenges, 4) modal analysis at various levels, including single cells, panels, rims, and full metaTire and n-Wheel configurations, 5) nonlinear deformation and stress analysis for single cells, panels, rims, and full metaTire and n-Wheel systems, and 6) 3D printing model slicing to generate optimal printing passes for NURBS models. Further details will be provided in the subsequent slides.

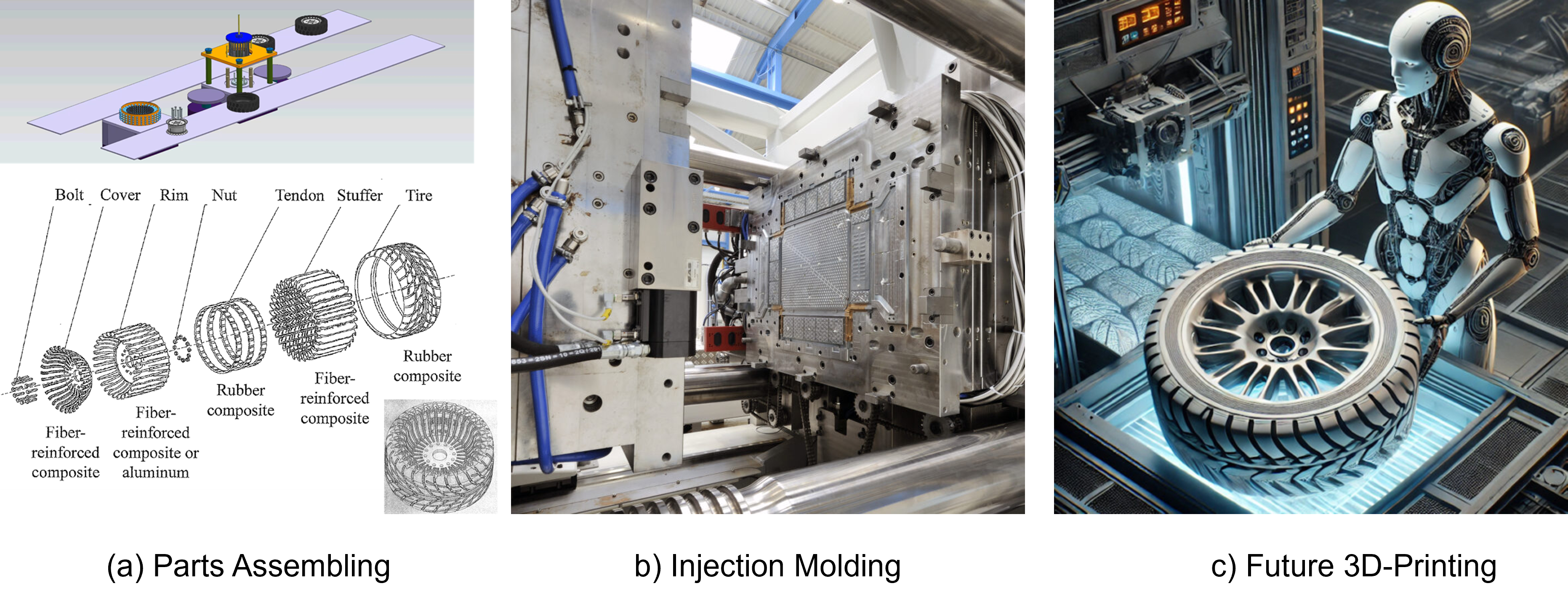

A key advantage of the n-Wheel concept, developed by N-Wheel Technologies, Inc., is its adaptability to be functionally designed and manufactured using various production methods. Figure 7 provides an overview of both current and potential future manufacturing processes for producing the physical n-Wheel. As shown in Figure 7, the n-Wheel can be fabricated through: a) an advanced assembly process, used to produce most of the n-Wheel prototypes shown in Figure 4, except for the bottom-right prototype (bike), b) injection molding, which was utilized to manufacture the n-Wheel for the bike displayed in the bottom-right corner of Figure 4, and c) a 3D-printing process, which has been employed to produce scaled prototypes for testing and concept validation purposes. An enhanced 3D-printing capability aimed at mass production is planned for future development. Additional details will be provided in the subsequent slides.

The metaTire™ and n-Wheel™ technologies are redefining the potential of airless tires. By eliminating the limitations of traditional pneumatic designs, these systems unlock new possibilities for enhanced performance, durability, and application diversity. From heavy-duty commercial vehicles to lightweight autonomous systems, these innovations are tailored to meet the evolving demands of modern mobility.

Our mission with metaTire™ is to set new standards in tire performance by achieving the following objectives:

These advancements position metaTire™ and n-Wheel™ as cornerstones of next-generation mobility, enabling safer, smarter, and more sustainable transportation solutions.

Our innovative n-Wheel™ technology redefines the possibilities of airless tire systems, offering a wide range of advantages that enhance vehicle performance, safety, and efficiency:

With enhanced lateral stiffness, n-Wheel™ ensures greater vehicle stability, delivering precise handling and improved performance, even in challenging driving conditions.

Adjustable vertical stiffness allows n-Wheel™ to adapt to varying loads, ensuring a smoother ride by minimizing vibrations and shocks for both drivers and passengers.

n-Wheel™ incorporates load-adaptive Negative Poisson’s Ratio (NPR) characteristics, dynamically adjusting to deliver precise functional performance under diverse operating conditions.

Its unique structure provides expanded design flexibility, making n-Wheel™ suitable for a variety of applications, from commercial vehicles to autonomous systems and electric vehicles.

By reducing overall vehicle weight and simplifying component complexity, n-Wheel™ lowers manufacturing costs while boosting fuel efficiency and energy savings.

Designed for the future, n-Wheel™ allows seamless integration with sensors, control systems, and other in-wheel intelligent components, paving the way for advanced applications such as autonomous vehicles and predictive maintenance systems.

With fewer components and longer-lasting materials, n-Wheel™ reduces waste and promotes sustainability, aligning with global efforts to create environmentally friendly mobility solutions.

Our innovative **n-Wheel™** technology has the potential to revolutionize mobility by addressing critical challenges and opening new frontiers in tire design and functionality. Beyond improving vehicle efficiency, n-Wheel™ has the capability to influence the fundamental aspects of suspension systems, vehicle design, and even the way autonomous vehicles operate.

By transforming how tires interact with vehicles and roads, n-Wheel™ technology could drive innovations in suspension systems to leverage its unique characteristics, resulting in smoother rides and more efficient designs. Additionally, it may influence vehicle architecture, enabling lighter and more compact designs that optimize energy consumption. For autonomous vehicles, n-Wheel™’s intelligent integration with sensors and data systems will enhance navigation precision, safety, and adaptability, reshaping the way autonomous driving systems operate.

(If the PDF doesn't open, try long-pressing the link and selecting "Open in New Tab")

ZD on Website of Mechnical Engineering, The University of Michigan

Never worry about a flat tire again. Our airless tires are puncture-proof, keeping you safe and worry-free.

With no need for inflation and minimal upkeep, our airless tires save you time and money while maintaining top performance.

Our airless tires are made from sustainable materials that help reduce environmental waste and offer a greener driving solution.

n-wheels offer a smooth, hassle-free driving experience for daily commuters and road trip enthusiasts alike.

Cut down on maintenance costs and vehicle downtime with n-wheels designed to keep your fleet on the move.

Conquer rugged terrains with confidence—n-wheels are built for adventure and extreme conditions.

Airless tires last significantly longer than traditional pneumatic tires, often reducing the need for replacements by up to 50%.

Our airless tires are available for a variety of vehicle types, including passenger cars, trucks, and off-road vehicles. Contact us for more information on specific sizes.

Yes, many airless tire designs offer lower rolling resistance, contributing to improved fuel efficiency.